Indiatech Pharma Exporters is a renowned manufacturer and exporter of high-quality Vacuum Tray Dryers, catering to the diverse needs of the pharmaceutical industry. With our extensive expertise and commitment to excellence, we provide reliable solutions for efficient drying processes.

As a trusted Vacuum Tray Dryer manufacturer, we specialize in designing and manufacturing top-notch drying equipment. Our Vacuum Tray Dryers are known for their exceptional quality, durability, and performance. They are crafted using high-grade materials and advanced technology to ensure optimal drying efficiency and product quality.

Indiatech Pharma Exporters prioritizes customization to meet the specific requirements of our clients. Our Vacuum Tray Dryers can be tailored to handle different capacities, materials, and drying conditions. We offer various customizable options, including temperature controls, airflow adjustments, loading and unloading systems, and advanced safety features.

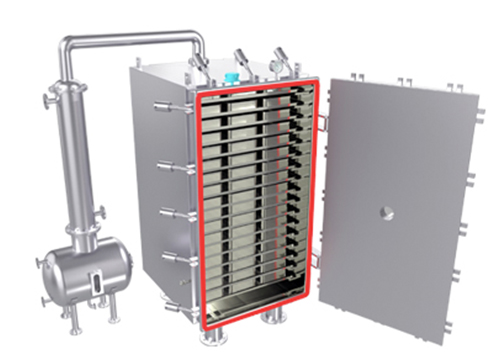

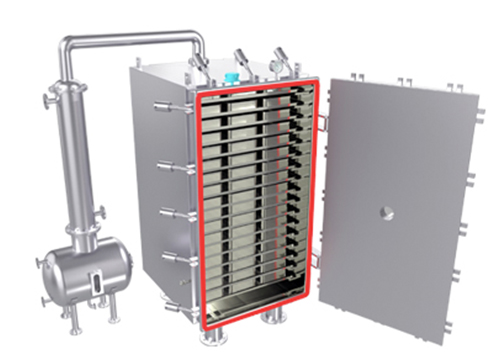

Our Vacuum Tray Dryers provide efficient drying solutions for pharmaceutical applications. They are designed to remove moisture and other volatile components from materials effectively. The vacuum environment accelerates the drying process by lowering the boiling point of moisture, resulting in faster and more efficient drying.

With our industry-leading expertise, we continually innovate our drying equipment designs. We incorporate advanced features to enhance performance, energy efficiency, and ease of operation. Our Vacuum Tray Dryers are designed for uniform heat distribution, precise temperature control, and optimal airflow, ensuring consistent and high-quality drying results.

Our dryers are specifically designed to meet the needs of thermal sensitive solid materials that easily degrade or undergo fermentation due to moisture absorption, which can ultimately affect the quality of the final product. Therefore, prior to the drying process, it is crucial to sterilize the materials to ensure that no foreign elements enter the vacuum dryer once it is operational.

Vacuum Drying is an efficient process that utilizes reduced atmospheric pressure to facilitate the drying of thermo-labile materials without the need for excessive heat. This method enables the removal and recovery of solvents from solid products as per specific requirements. The drying time for maintaining the optimal quality of the materials can range from 12 to 48 hours, depending on the process specifications. The efficiency of the drying process is enhanced by the circulation of hot water or steam through hollow shelves. The temperature is meticulously controlled and maintained near the boiling point of the drying cycle. Vacuum drying is suitable for various industries such as food, pharmaceuticals, agriculture, biological product processing, chemical manufacturing, and the AP/API/nutraceuticals/bulk drugs industry, where moisture removal is a critical part of the overall process.

At Indiatech Pharma Exporters, we prioritize customer satisfaction and strive to exceed expectations. We offer comprehensive technical support and assistance in selecting the right Vacuum Tray Dryer for specific applications. Our team of experts is committed to delivering reliable solutions and exceptional service.

Choose Indiatech Pharma Exporters for high-quality, customizable Vacuum Tray Dryers that offer efficient drying solutions. With our versatile drying machines, you can achieve superior drying results, improve production efficiency, and meet the stringent quality standards of the pharmaceutical industry.

Salient Features of Vacuum Tray Dryer :

- Unit spares, including the condenser, receiver, radiator, electrical heaters, pipes, and side walls, are manufactured using excellent quality and durable materials to ensure lifelong service.

- The circulation pump and vacuum pump are heavy-duty and bear the ISI mark, ensuring reliability in operation.

- The vacuum chamber is equipped with high-grade insulation sheets of proper thickness, along with intensive sealing gaskets (made of silicon), which enhance the vacuum drying process.

- The hot water tank is constructed with high-quality steel and further insulated to prevent heat loss, resulting in significant production cost savings. This tank is equipped with a solenoid-controlled pneumatic operated valve located at the hot water inlet, providing better control over the entire operation.

- The drying trays are portable, made of high-grade steel, and welded with zero fatigue. Special care has been taken during their manufacturing to eliminate sharp edges, requiring special bending techniques to achieve a state-of-the-art design.

- All pipes are internally coated with a special rust-free material to ensure long-term operation. Various flanges, valves, jackets, and drain valves of superior quality are strategically mounted for easy daily and preventative maintenance by operators.

- The main vacuum chamber is equipped with safety devices such as an explosion vent or rupture disc, adding an additional layer of safety. A pressure release valve is also installed in the steam line, requiring regular calibration.

- Operators can easily monitor various parameters as required, as visible gauges are conveniently located, making the unit highly versatile and facilitating the vacuum drying process. Most parameters are digitally displayed and accompanied by process control switches and alarm systems, ensuring precise and efficient operation.

- The main chamber is equipped with a transparent glass window for manual observation and close monitoring of the drying process.

- All electrical components are of high quality and utilize fireproof wiring to prevent accidents during the drying process.